NEWS

"Smart Manufacturing" kicks off

Updated:

2021-09-30 10:53

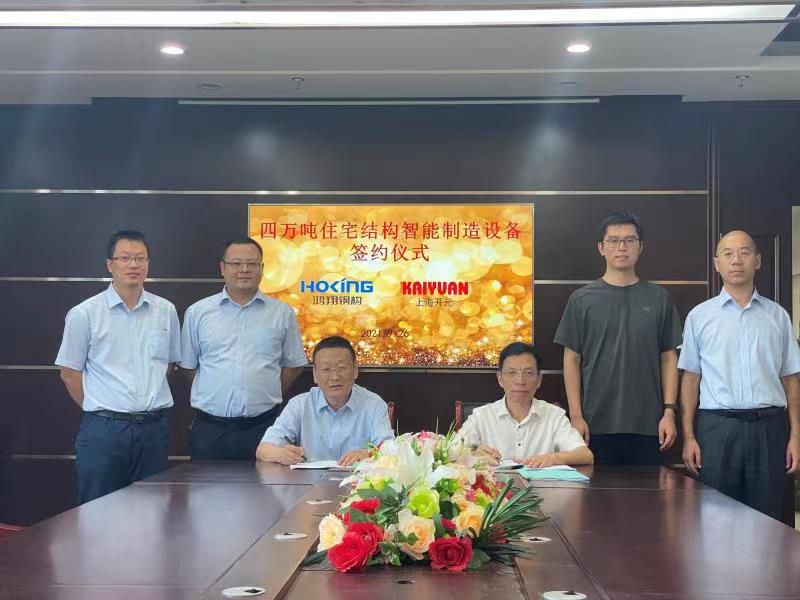

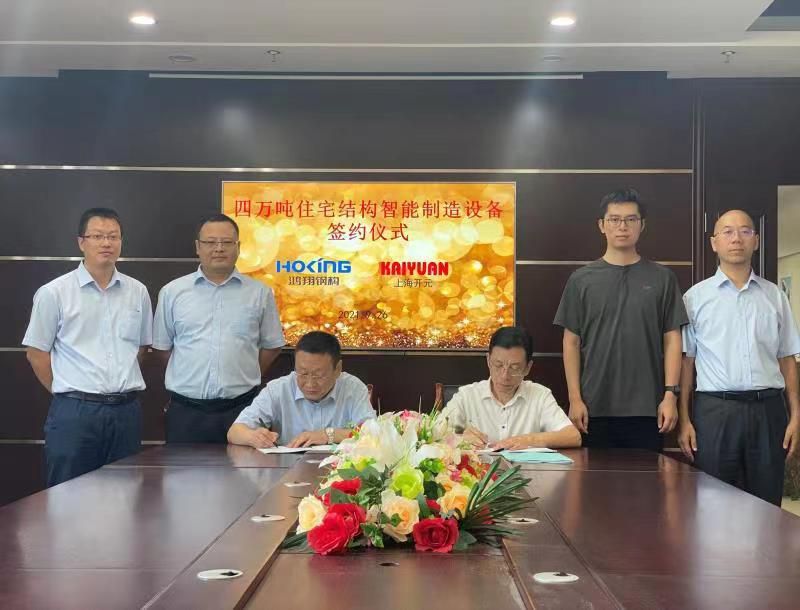

September 26th is a special day for the company's strategic development! At 15:58 in the afternoon, the company reached a final cooperation intention with Shanghai Kaiyuan on the equipment investment of our company's intelligent manufacturing project, and signed the relevant cooperation and technical agreement of "40,000 tons of residential structure intelligent manufacturing equipment" on the spot. So far, the strategic project of "Hongxiang Steel Structure Intelligent Manufacturing Experimental Workshop" has officially kicked off! It has taken a landmark step for the company's development in the field of steel structure prefabricated housing!

The origin of the strategic concept of "intelligent manufacturing" can be traced back to 2019. After many technical exchanges and brainstorming with Hangzhou Timoshenko Architectural Structure Design, the company has a preliminary but in-depth understanding of the development of residential steel structures at the technical and system levels. At the end of the same year, the company officially reached a strategic cooperation relationship with Timoshenko on the steel structure implicit frame residential system, and jointly applied for the "Ministry of Housing and Urban-Rural Development Science and Technology Research and Development Project 2020-K-113" with Timoshenko and other eight companies to jointly study and explore the major topic of "Standardization of Steel Structure Residential Components and Intelligent Construction Research and Application". Among them, the sub-topic of intelligent manufacturing of residential structural components is the main research direction undertaken by our company. After about a year of continuous discussion, research and technical demonstration with all parties in the industry, and countless communication, docking and testing of needs and technical indicators with equipment manufacturers, we finally determined the final production process, tooling, and certification of logistics automation welding intelligent solutions for the relevant production lines of intelligent manufacturing with Shanghai Kaiyuan on September 26, 2021. The main core welding stations of the production line adopt the Japanese Kobelco welding technology system. In addition, the automatic production line for component coating will adopt silane plus powder spraying process, which will greatly improve the coating efficiency and coating quality, and meet the highest national environmental protection standards for paint coating.

In the next step, the "Residential Structure Intelligent Manufacturing Experimental Workshop Project" will tackle difficulties in the informatization, digitization, and intelligence of the experimental workshop in the management connection, the research and development of the Max system, and the interconnection of the BIM management system, and finally realize the experimental workshop with intelligent manufacturing, information management, and digital control and accounting, providing a "model" for the industrialization promotion, application, and demonstration of residential structure intelligent manufacturing, and providing a foundation and guarantee for the development of steel structure prefabricated residential buildings.

More information